Introduce our customer

Manufacturing's first Industrial IoT Platform

Affordable, Simple & Reliable

We provide prorietary end-to-end Industrial IoT Platform to improve efficiency, safety, and quality with innovative business model that “EVERYBODY CAN USE”

Increase Efficiency,

Maximize Profitability

Technimal provide effective and flexible industrial IoT platform to make digital tranformation in your factory. Easily Collect and Analyze the data from any equipment and visualize on the application to reduce downtime, increase efficiency, and maximize profitability in real time.

Connect

Easily connect, collect, and visualize the data from any necessary machine on the industry

Analyze

Open the deeper insight to analyze problem in real-time

Take Action

Decrease downtime with responsive action by sending alert to the right person at the right time

"20% DECREASE IN DOWNTIME"

Welcome to digital world

Learn how Technimal lead industry to the world of digital factory

Connect with your factory

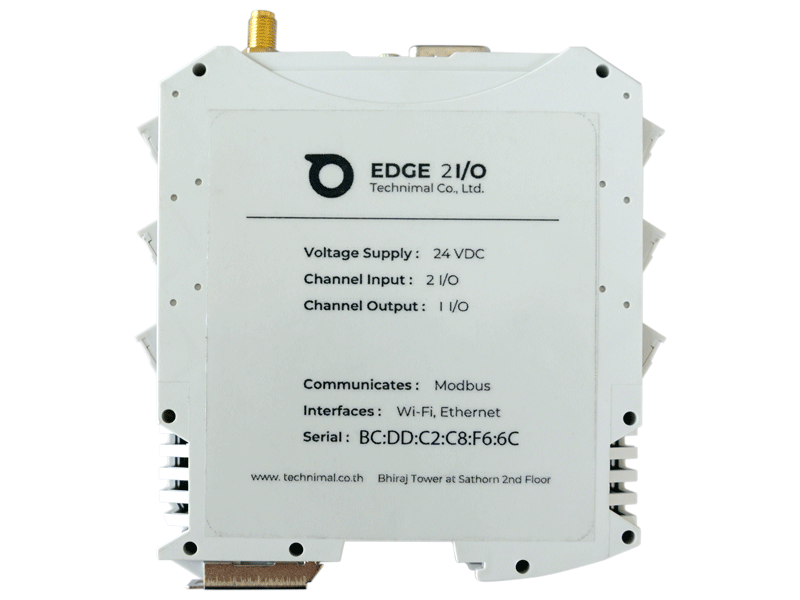

EDGE

Technimal Edge is a plug and play (PnP) device to easily collect the data and sends the information wirelessly to our platform. It has high flexibility to easily capture the data from any type of equipment and provide actionable machine insight for manufacturer.

Cloud Platform

Technimal IoT platform gather the data and secure it in one centraliized location which can be used to remote access from any place in the world. (Microsoft Azure, Amazon Cloud, Artemis Cloud)

Application

Technimal application visualize platform delivery various application to make an action such as real-time dashboard, historical report, and alert by text, email or phone call to operator.

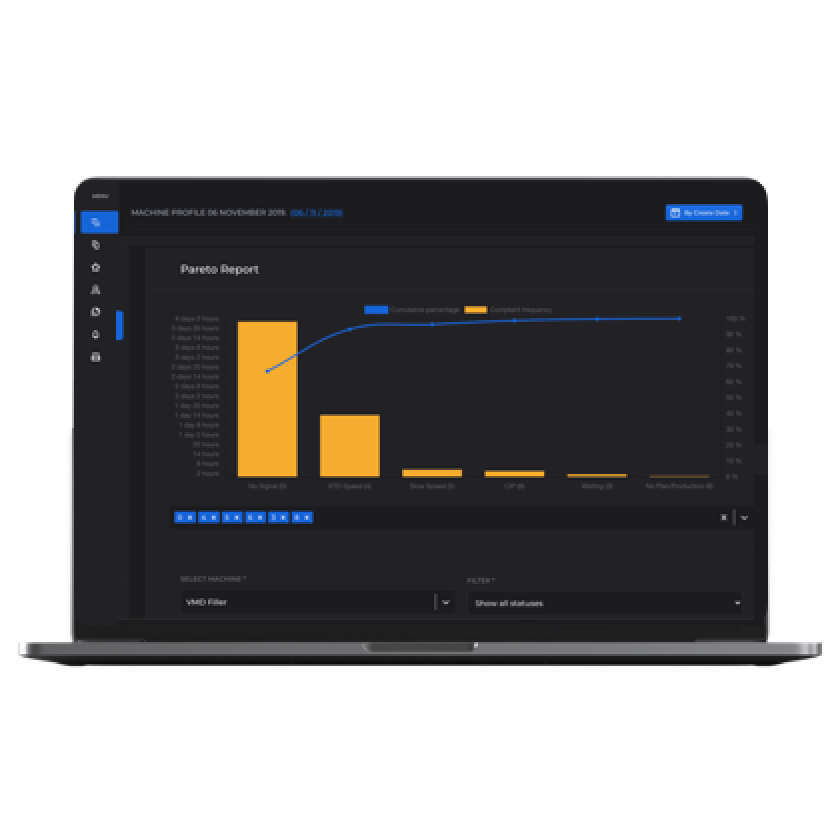

Technimal Application

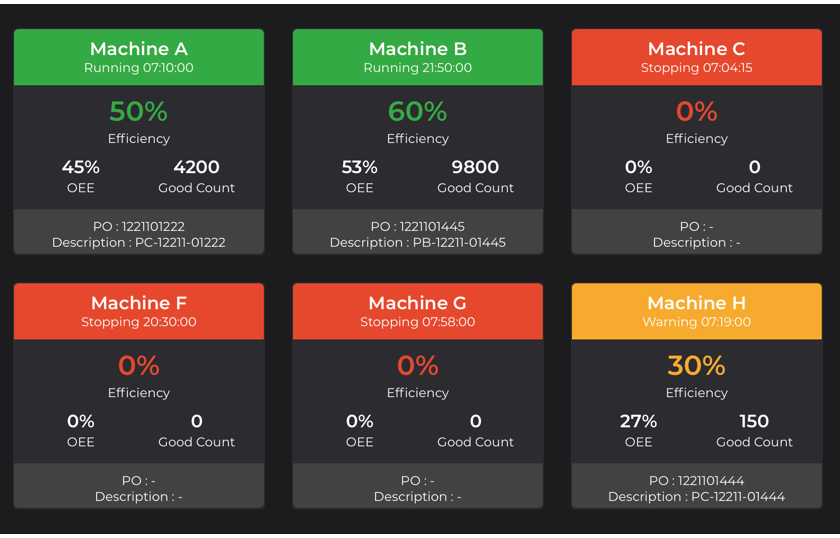

Production monitoring

Increase performance efficiency with real-time OEE, downtime, and performance report

Available for upfront payment or monthly subscription

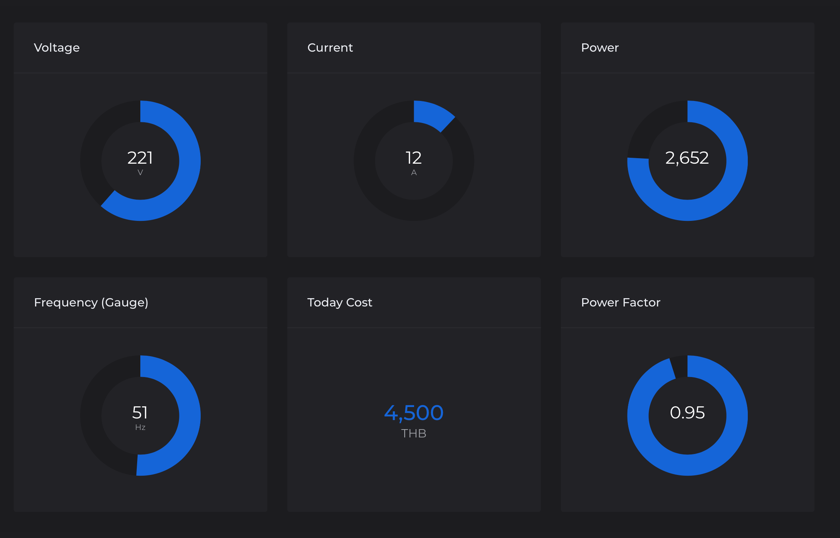

Condition monitoring

Quick responsive to machine condition with real-time monitoring

Available for upfront payment or monthly subscription

Predictive Maintenace

Analyze, predict, and avoid all type of failure on the machine in your factory

Available for upfront payment or monthly subscription

Process Optimization

Empower of workforce with process insight to optimize the workflow

Available for upfront payment or monthly subscription

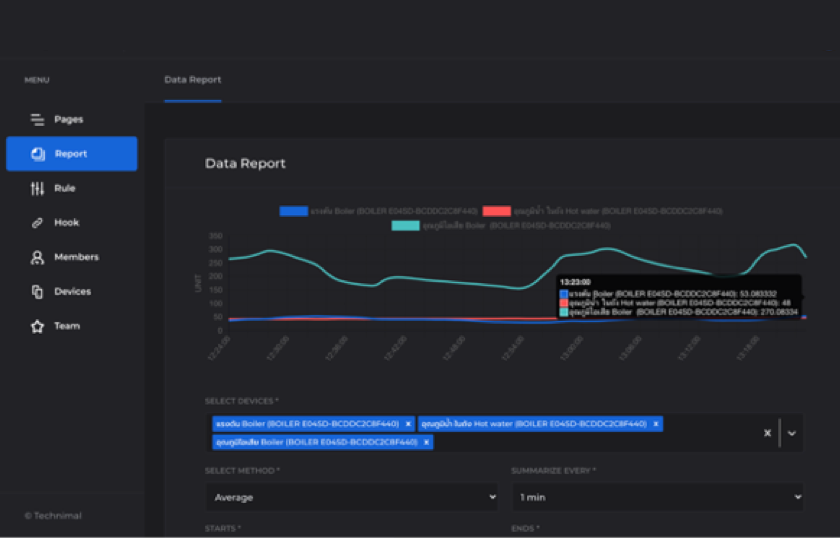

The analytics case study

Digital Transformation in Food & Beverage Factory

To improve the productivity in food and beverage factory, we will collect and analyze the data to monitoring and track down the downtime in the process.

The analytics case study

Increase efficiency in Steel Pipe Factory

To increase the efficiency of steel pipe factory, we will collect and analyze the data to monitoring and control it.

Our Unique Values

Data efficiency

Collect small quantity but high quality data

Simple installation

One box to connect everything

End-to-End Service

Assessment, Virtual Consultation, Installation

Low initial cost

Reasonable and reachable for every factory

Our success story

Heavy Machinery

Food and Beverage

Energy

Heavy Machinery

[elementor-template id=”648″]

Food and Beverage

[elementor-template id=”670″]

Energy

[elementor-template id=”680″]

Technimal Partners

- (+66) 02 055 6196

- [email protected]

- Sumipol Building @ On Nut